Clever Design Fits Lot Traceability System into Tight Spaces

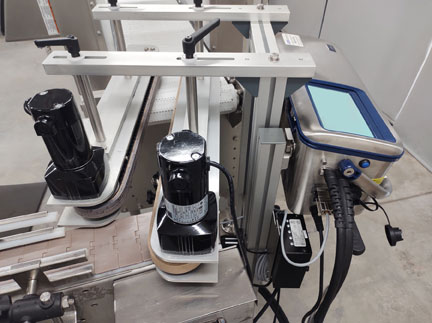

Wall, NJ: The Pharmafill(TM) Bottle Bottom Coding Package (BBCP) from packaging machinery manufacturer Deitz Co., Wall, NJ (www.Deitzco.com), features a clever hugger belt conveyor design that allows both automated printing on bottle bottoms and powered transfer at 90-degree angles at the same time without slowing, stopping, rotating, diverting or otherwise disrupting the bottle flow. Mounting dual hugger belts in an offset position at the desired turn radius, the novel bottle coding system enables food, pharmaceutical, nutrition, and other manufacturers, and contract packagers, to automate lot traceability code printing despite operating in tight spaces or within restrictive packaging line configurations.

The Bottle Bottom Coding Package automatically accepts filled or empty bottles from a standard conveyor, grips them between the dual, offset hugger belts, and transfers the bottles at a right angle over a continuous inkjet printer or laser marking device for adding the serial numbers, lot codes, logos, and other information onto the bottom. When completed, the printed bottles are released downstream to a turntable or standard conveyor. The Bottle Bottom Coding Package integrates the company’s Pharmafill BCV1 Bottomless Conveyor with a compatible printing system suitable for installation as a single unit.

For more information, contact the sales staff, Deitz Co., Inc.; 1750 Route 34, PO Box 1108, Wall, NJ 07719 USA; 732.681.0200; Fax 732.681.8468; www.deitzco.com; sales@deitzco.com.

# # #