Pharmafill(TM) CS2 Cottoner Invites Fast Inspection for Wear

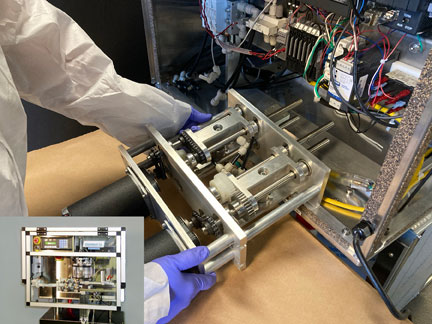

Wall, NJ: The Pharmafill(TM) CS2 automated cotton inserter from packaging machinery manufacturer Deitz Co., Wall, NJ (www.Deitzco.com), features a clever, removable drive system that allows 360-degree visual inspection for wear for fast, easy maintenance. Devised to promote uninterrupted cotton inserting and incentivize preventative maintenance, the self-contained drive system permits easy, ergonomic assessment of the drive belts, chains, chain sprockets, sealed roller bearings, mating rollers, and the roller pressure air cylinder linkage without disassembling the entire cotton inserting machine. After any worn parts are replaced, the removable drive system may be slid back into position and returned to service.

Ideal for contract packagers and pharmaceutical and nutrition product manufacturers who require dependable operation and lack expert maintenance technicians on staff, the Pharmafill CS2 cottoner with removable drive system may be safely extracted with a common wrench and hex keys by removing the rear and one side panel, and disconnecting the motors, air cylinder, and rollers. This maintenance check is recommended once per year to ensure the cotton feeds smoothly from the roll and tears cleanly at the desired length every time.

The Pharmafill CS2 automatically separates cotton into individual pieces of uniform length from a continuous roll and inserts them into the center of solid dosage bottles with 100% accuracy. The cottoning machine is designed and manufactured at the company’s Wall, New Jersey headquarters and delivered with a full warranty.

For more information, contact the sales staff, Deitz Co., Inc.; 1750 Route 34, PO Box 1108, Wall, NJ 07719 USA; 732.681.0200; Fax 732.681.8468; www.deitzco.com; sales@deitzco.com.

# # #