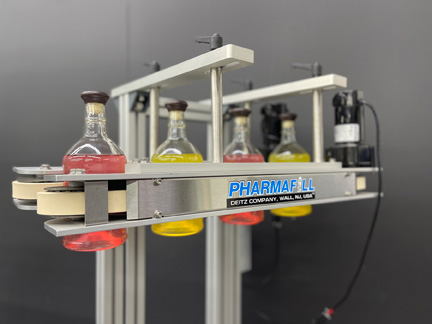

Pharmafill(TM) BCV1 Adjusts Fast for Wide, Narrow Diameters

Wall, NJ: The Pharmafill(TM) BCV1 Bottomless Conveyor from packaging machinery manufacturer Deitz Co., Wall, NJ (www.Deitzco.com), features a proprietary hugger belt design that quickly adjusts in width with no tools to accommodate a wide range of bottle sizes. Allowing the distance between the two hugger belts to be changed in seconds from as wide as 6.25 inches to as narrow as zero inches, the versatile Bottomless Conveyor enables beverage, nutrition, pharmaceutical, and other bottling, manufacturing, and co-packing companies to transfer multiple products and/or sizes using the same conveyor. During changeovers, an operator simply rotates hand cranks to switch from powdered supplement tubs, liquor bottles, or jugs to mascaras, dropper bottles, vials, or other products.

Set on casters to roll easily to a filling or packaging line, the portable Bottomless Conveyor is typically installed above a printer to automatically apply lot traceability coding on the bottle bottom, and anywhere that bottle spacing, speed control, or powered transfer from one stage in the line to another stage is needed. The BCV1 captures bottles from an adjoining conveyor and gently suspends them between the hugger belts while advancing them to discharge onto a turntable or conveyor downstream.

The Bottomless Conveyor is manufactured at the company’s Wall, New Jersey, headquarters. Testing is offered on-site to verify the conveyor is compatible with the required bottle style.

For more information, contact the sales staff, Deitz Co., Inc.; 1750 Route 34, PO Box 1108, Wall, NJ 07719 USA; 732.681.0200; Fax 732.681.8468; www.deitzco.com; sales@deitzco.com.

# # #