Versatile Pharmafill(TM) NB1 Includes Extra Parts to Accommodate Range of Bottles

Wall, NJ: The PharmafillTM NB1 neck banding machine from packaging machinery manufacturer Deitz Co., Wall, NJ (www.Deitzco.com), features a complete change parts kit as standard. Included to expand the range of bottle sizes and shrinkband widths that may be banded on the automated packaging machine, the change parts kit comprises an extra spreader assembly to match wide lay flat widths, an extra plunger assembly to suit tall bottle caps and long seal lengths, and band holders in two different sizes that steady the neck band for application after it is cut from the roll. The change parts kit helps packaging managers apply neck bands and sleeve labels on bottle caps ranging from 14 mm to 76 mm in diameter using shrinkbands ranging from 25 mm to 123 mm in width.

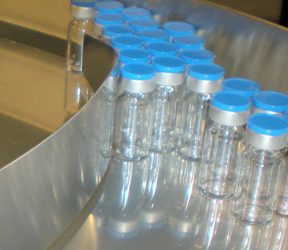

Devised for contract packagers and food, beverage, nutrition, and pharmaceutical manufacturers, the change parts kit supports fast changeovers with easy setup to minimize line downtime and help capitalize on the full range of neck banding capabilities. The tamper-evident neck band applicator automatically applies shrink bands and printed full or partial sleeve labels of any heat shrinkable material onto glass, plastic, and metal bottles, jars, tins, vials, and other containers.

The Pharmafill NB1 with the change parts kit is designed and manufactured in the company’s Wall, New Jersey, headquarters. Machine and product testing are offered on the company’s in-house testing and training line.

For more information, contact the sales staff, Deitz Co., Inc.; 1750 Route 34, PO Box 1108, Wall, NJ 07719 USA; 732.681.0200; Fax 732.681.8468; www.deitzco.com; sales@deitzco.com.

# # #